Neoxis is the well-known Electrical Audit company facilitate the Power consumer for safe Electrical installation and utilization.

We provide the following services under Electrical Audit

Electrical Safety Audit

Electrical safety audit consists of on-site inspection and testing; and coming up with recommendations after data analysis.

“The country has witnessed several devastating fires that have claimed hundreds of innocent lives and damaged property worth billions and most of the reason of fire is Electrical Short circuit”

Scope of the Electrical Safety Audit:

-

Verification of statutory compliance with respect to CEA- 2010/ Indian Electricity rules 1956.

-

Insulation testing for cables.

-

Thermal Imaging - Identification of Hot spots at the termination of Cables and wire in the Panel and DBs

-

Earth Pit Resistance Measurement online or offline

-

Adequacy / Overloading of Cables and MCB/MCCB/RCCBs by carrying out load current measurements and compared against cable current carrying capacity calculation

-

Load Imbalance Testing

-

Earth Leakage current testing

-

Visual Inspection of overall Electrification

-

Review of electrical preventive maintenance system (including tests, documentation, history cards, etc).

-

Review of electrical accidents and near misses in the plant to identify the root causes

Power Quality Audit (Harmonics):

The Power Quality Audit (PQA), is a process of investigation of the reliability, efficiency and safety of an organisation’s electrical system.

It has been found that with increased use of electronic components like UPS, Computers, Drives those creates disturbance in Electrical system that could lead to damaged equipment, consequently reducing its working efficiency and shortening the life span.

We analyze the following data by using Power Analyzer in the Electrical System

-

Harmonic Analysis, in the waveforms for AC power.

-

Power Factor

-

Phase-phase/Neutral RMS voltage variations.

-

Variation in voltage magnitude like fluctuations, transient over voltages, voltage dips and interruptions

-

Transient voltages and currents

-

power-frequency variations

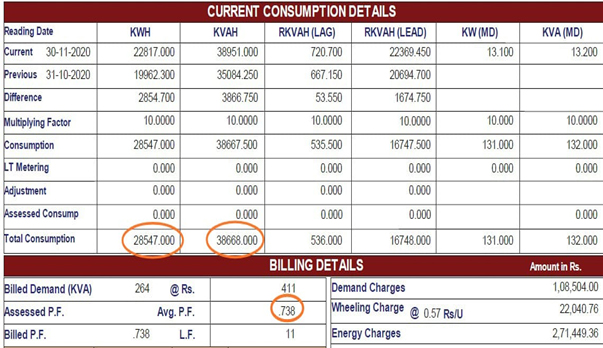

Electricity Consumption Bill Analysis

The cost of Electricity is increasing day by day. We have observed that a lot of consumers do not know how to interpret their Electrical Consumption bill. Our experts and qualified teams help the consumers to reduce the bill amounts by undertaking proper analysis in terms of appropriate tariff

We check the following parameter

-

Demand penalty, or a gap between contract demand and recorded demand,

-

PF penalty/ incentives,

-

Exemption of government duty as applicable, etc.

-

Appropriate applicable tariff on the consumer categories

Lighting Audit (Lux Level)

Lighting Audit is an onsite walkthrough of an existing facility, to document the current lighting conditions and determine where energy saving can be achieved, by replacement of lights with energy saving lights, or reducing excess light and installation of additional lights in case of lower lighting level. It can be conducted for both exterior and interior spaces.

We measure the existing light level by using light meter (Lux Meter) and compare it with the standard recommended light level for different type of uses.

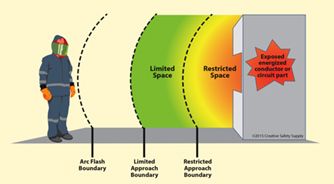

Arc Flash Analysis:

As per NFPA 70 E, Section 130.5, an Arc Flash Risk Assessment is done to determine the risk, practices required for safety related work, arc flash boundary, incident energy at the working distance, and the PPE that people shall use within the arc flash boundary. This assessment shall be reviewed at intervals not exceeding 5 years.

These calculations are based on available short circuit current, protective device clearing time and distance from the arc. Calculations of incident energy levels and flash protection boundaries will be completed for all relevant equipment busses.

Lightening Protection Audit

The goal of lightning protection systems is to transport lightning current safely to ground.

With the increase in Sensitive electrical equipment’s in the workspace, the need for protection against the dangers of Lightning has been increasingat an alarming rate; we review the following points in the audit:

-

Reviewing existing lightning protection system with reference to national & international standards

-

Study of maintenance aspects of lightning protection

-

Suggest suitable corrective actions in existing system, if required

-

Risk Assessment Calculation Considering all elements as described in the IEC 62305 Part 2.

-

Structure Dimension – Collection Area Calculation

-

Environmental Influences

-

Adjacent Structure Contribution factor derivation

-

Existing protection measure

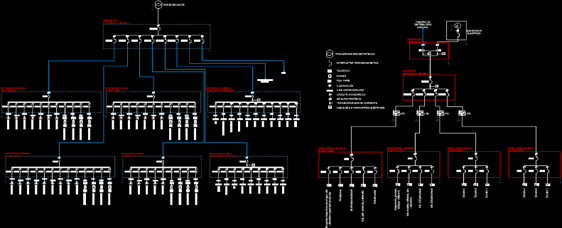

Electrical Design Validation Audit

Design Validation play a vital role for the perfect and safe Electrical installation, we review the Design on the basis of clients actual Power requirement with proposed design. Review of Design helps customer to take the corrective action in beginning itself.

Design Validation Audit Assessment:

- Study and understand the customer power requirement

- Review the proposed Single Line Diagram for proper distribution

- Review the Cable size on the basis of current carrying capacity after applying de-rating factor

- Review Protection switchgear (SFU/MCCB/MCB/ELCB) with proper discrimination

- Review of Lighting Lux level design as per lighting norms

- Review of Earthing Pit requirement and Earthing conductor

- Review the proposed BOQ and compare it with the design drawing

Electrical Contractor Bill Certification:

Billing is the documentary aspect of the work done through which payments can be made to the person involved in the contract and is responsible to complete the work. Incomplete billing can cause considerable losses to the contractor and the client. Hence, bills should be perfect and self-explanatory at any stage of work.

- Checking / Certification of bills and invoices of vendors, and contractors on the basis of detailed Work / Purchase Order payment terms.

- Review the Measurement Sheet certified by the Site engineer and checking all the certified quantity mentioned in proper head.

- Analysis of variation claims by Contractors / Vendors and closing of the same.

- Checking and certification of Extra items used at site as per Tender/ Work Order terms.